No products in the cart.

Picking the right rolling mill can be difficult, but we are here to support you every step of the way. All our rolling mills are designed to last an extremely long time, so picking the right one is key. This guide is designed to help your selection process and make sure you get the mill you need and want.

1.

Powered or manual rolling mill?

The first question is do you want a manual rolling mill, which you turn via a handle or a motorised rolling mill that is turned by an electric motor. There are two factors to consider: (i) the amount of usage the rolling mill will get (if it’s continuous or ‘high’ then a powered mill has efficiency and ease of use benefits); and (ii) your budget. Powered mills are affordable, but considerably more expensive than manual rolling mills. Powered rolling mills Manual rolling mills

2.

If manual, do you want a reduction gearbox?

If you decide on a manual mill, a gearbox can help to make turning the crack/handle a lot easier. A direct drive manual mill, which does not have a gearbox requires some physical effort to turn the handle and mill metal. A gearbox transfers each turn of the handle via a gearbox that significantly reduces the amount of effort and force needed to turn the mill. If you want a reduction gearbox on your mill, look for products with ‘R’ in the name which stands for ‘reduction gearbox’. Gearbox Rolling Mills Direct Drive Rolling Mills

3.

What do you want to use the mill for?

Durston creates four kinds of rolling mills; round mills, wire mills, flat mills and combination mills. Which one you choose depends on what you want to use the mill for. If you want to use the mill to imprint patterns onto sheet metal (or to roll sheet metal), then a ‘flat’ mill is the right choice (signified with an ‘F’ in the product name). If you only want to roll square wire, then a ‘wire’ mill (signified with a ‘W’ in the product name) is your best bet. If you want a combination of wire and flat rolling a ‘Combination’ mill (with a ‘C’ in the product name) is perfect. Looking for round wire rolling, then pick one of our ‘Round’ mills (with an ‘R’ in the product name). Combination Rolling Mills Flat Rolling Mills Wire Rolling Mills Round Rolling Mills

4.

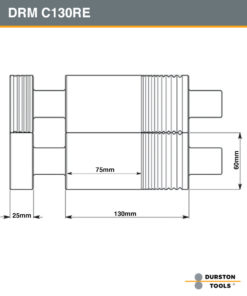

What mill length?

Longer mills lengths offer a greater choice in wire milling grooves or a larger area for flat milling. Durston rolling mills range from an entry-level 80mm long mill right up to 200mm. The size of the mills you choose is a personal choice based on the usage you foresee, but remember the longer the mills, the greater the flexibility, so think about your needs now and likely needs in the future to make sure you pick something you can grow with.

5.

Do you need extra flexibility?

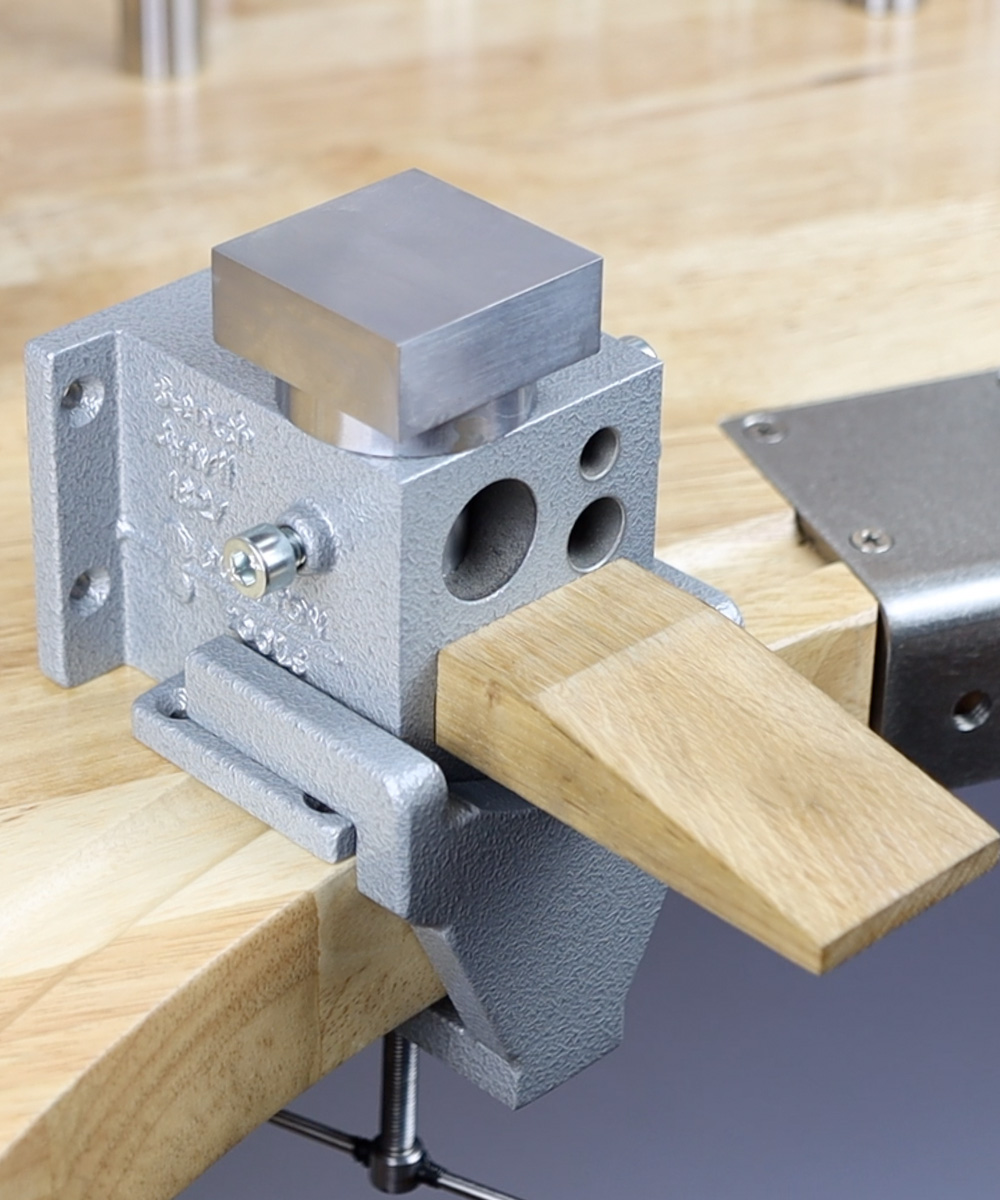

Side extensions are extra rollers on the side of the mill. Side extensions (signified with an ‘E’ in product names) add flexibility to any mill; for example, say you typically roll flat metal, but occasionally need to D shaped wire. In this case, having side extensions can be a great addition to your mill. WITH SIDE EXTENSIONS

6.

What’s important to you – lowest price or highest quality?

All Durston Tools rolling mills are designed to last with the highest quality components and manufacturing rigour. However, we are aware that some customers are working to a budget and to this end, Durston mills come in a number of ranges to suit your budget. The DRM mills (in both powered and manual) are our highest specification range of mills, with no compromise on design, quality or components. DRM mills are found in jewellery manufacturing workshops all over the world and offer years of reliable service. Our Agile & TUI ranges have been created with the same focus on quality, but with a focus on their core function in order to keep costs as low as possible. The Agiles are a lower cost option due to savings in lighter castings and a T bar instead of handwheel but are still designed to deliver years of reliable rolling.

If budget is a factor, then there is the mini range. A hugely popular mill for the budget market.

Mini Rolling Mills Agile Rolling mIll Range DRM Rolling mills Range7.

Going big. Double mills and floor standing rolling mills.

For busy professional jewellery manufacturing environments, Durston offers a range of double rolling mills and floor standing mills. Double mills feature two full sets of rolling mills providing a dedicated wire mill and a dedicated flat mill, in both powered and manual models. For high-end production environments, we also have the floor standing powered range of mills, which offer the ‘Rolls Royce’ milling experience with powered milling on its dedicated footing. Double sided rolling mills Floor standing rolling mills

8.

Any questions, ask us!

We are standing by to help you make the right decision and choose the mill that is just right for you. Just call, email or live chat with us now to speak with our sales team who will be happy to recommend some product options for you. Get in touch